What are the basic parts of CNC machine tools?

A CNC machine tool is a machine tool that controls the machining of a workpiece through a pre-written program, which uses a computer control system to control the machine tool for various operations. CNC machine tool base parts are the core components of CNC machine tools, the following will introduce the CNC machine tool base parts include what.

Basic parts of CNC machine tools-Disappearing mold gantry columns

CNC machine tool is a kind of high-precision, high-efficiency machinery and equipment, widely used in various industries for parts processing. The basic parts of CNC machine tools refer to the parts that constitute the overall structure of the machine tool, in which the gantry column is an important basic part of CNC machine tools.

Basic parts of CNC machine tools - gantry crossbeam

Gantry crossbeam is a kind of basic parts in CNC machine tools, it is an important part of CNC machine tools, used to support and fix the main moving parts of CNC machine tools. Gantry crossbeam is usually made of high-strength cast iron or welded structure, which has the characteristics of strong bearing capacity and good rigidity.

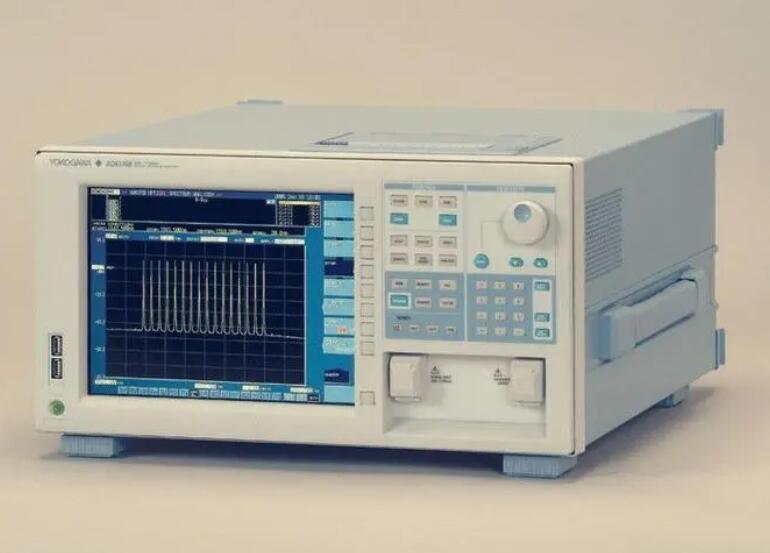

Machine Tool Industry - Italian GNRS5 Direct Reading Spectrometer

Italy GNRS5 Direct Reading Spectrometer is a high-precision measuring instrument used in the machine tool industry to analyze and test the spectral properties of materials. Spectrometer is a kind of instrument that uses the characteristics of light to analyze the material. By measuring the spectral phenomena such as absorption, emission and scattering of the material at different wavelengths, information on the composition, structure and properties of the material can be obtained.

Japan Sabu NSB500 Rapid Analyzer

The NSB500 Rapid Analyzer is an instrument developed by a Japanese company, Sabu, for the rapid analysis of the composition and properties of samples. The instrument is equipped with a number of advanced technologies and features that enable the analysis to be done quickly and accurately in a short period of time.

Machine Tool Industry-Steel 3000 Carbon and Sulfur Analyzer

Steel 3000 Carbon and Sulfur Analyzer is a professional instrument for determining the carbon and sulfur content in steel. Steel is a widely used material in the machine tool industry, and its carbon and sulfur content directly affects the performance and quality of steel. Therefore, it is very important to accurately measure and control the carbon and sulfur content in steel.

Introduction to CNC machine tools

A numerical control machine tool is an automated machine tool equipped with a programmed control system, which is short for Computer numerical control machine tools. The control system can logically process the program with control code or other symbolic instructions, and decode it, with coded digital representation, through the information carrier into the numerical control device. After the calculation and processing by the CNC device to send out a variety of control signals to control the action of the machine tool, according to the drawing requirements of the shape and size of the parts automatically processed out.

CNC machine tools have those characteristics compared with traditional machine tools?

Processing parts on CNC machine tools, mainly depends on the processing program, it is different from ordinary machine tools, do not have to manufacture, replace many molds, fixtures, do not need to frequently re-adjust the machine tool. Therefore, CNC machine tools are suitable for the processing of parts for frequent replacement of the occasion, that is, suitable for single-piece, small batch production and the development of new products, thus shortening the production preparation cycle, saving a lot of cost of process equipment.

Basic components for CNC machine tools

The basic components of a CNC machine tool include the machining program carrier, the CNC control, the servo drive, the main body of the machine tool and other auxiliary devices. The basic operating principles of each component are summarized below.